Unlocking the Potential of Sheet Metal CNC: A Comprehensive Guide

Release time:

2025-08-03

In the realm of manufacturing and mechanical processing, particularly within the field of sheet metal fabrication, CNC (Computer Numerical Control) technology plays a pivotal role. Sheet metal CNC machining refers to the automated control of machining tools via computer programming to create complex parts and components from flat sheets of metal. This process is increasingly favored for its precis

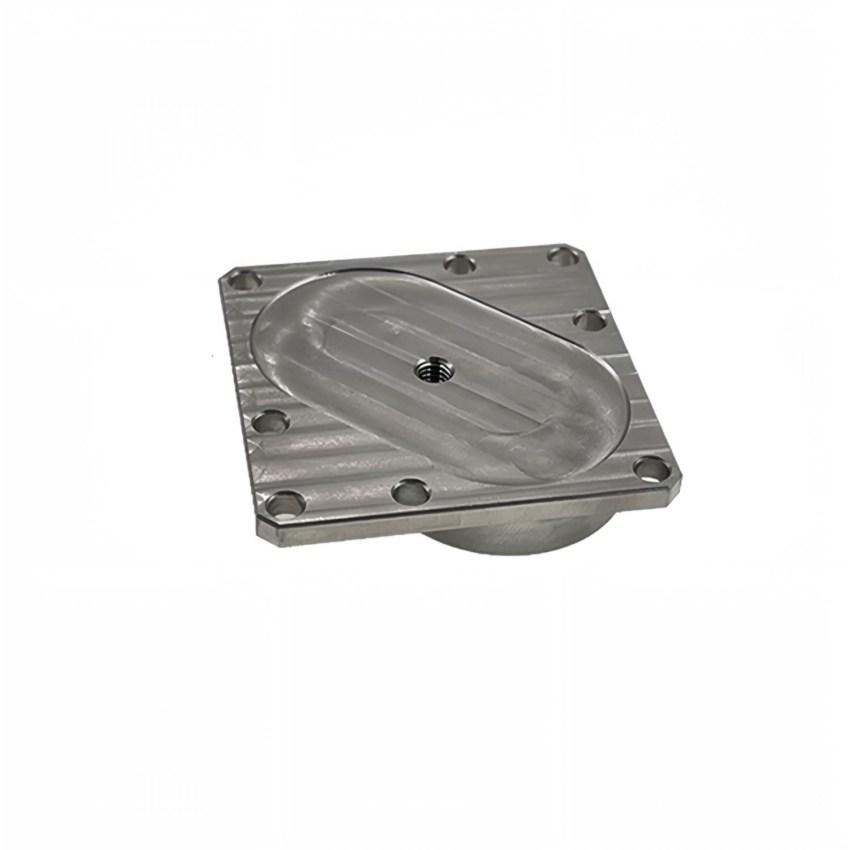

In the realm of manufacturing and mechanical processing, particularly within the field of sheet metal fabrication, CNC (Computer Numerical Control) technology plays a pivotal role. Sheet metal CNC machining refers to the automated control of machining tools via computer programming to create complex parts and components from flat sheets of metal. This process is increasingly favored for its precision, efficiency, and versatility.

One of the primary advantages of using sheet metal CNC is its ability to produce intricate designs with high accuracy. Traditional machining methods often require extensive manual intervention and can lead to human error. In contrast, CNC technology minimizes variations in production, ensuring that each piece is consistent with the original design specifications. This level of precision is critical in industries where tolerances are tight and quality control is paramount.

The sheet metal CNC process typically involves several steps: design, programming, machining, and finishing. Initially, a detailed design is created using CAD (Computer-Aided Design) software, which outlines the specifications of the desired part. Once the design is finalized, it is transferred to CNC programming software that translates the design into machine-readable code. This code directs the CNC machine, guiding tools such as lasers, plasma cutters, or routers to execute the required operations on the sheet metal.

Another significant benefit of sheet metal CNC machining is its efficiency. The automation of the cutting and shaping processes greatly reduces production times compared to manual methods. This efficiency translates to lower labor costs and faster turnaround times for projects, making businesses more competitive in the market. Additionally, CNC machines can operate continuously, with minimal downtime, further enhancing productivity.

Moreover, the versatility of sheet metal CNC extends beyond simple cutting. It can handle various operations such as bending, punching, and forming, making it suitable for a wide range of applications across multiple industries. From automotive components to electronics housings, the ability to work with different materials like aluminum, stainless steel, and copper allows manufacturers to meet diverse customer demands.

In conclusion, sheet metal CNC machining is revolutionizing the manufacturing sector by offering unmatched precision, efficiency, and adaptability. As industries continue to evolve and demand more complex components, the role of CNC technology in sheet metal processing will undoubtedly grow, making it an essential tool for professionals in the mechanical processing field. Embracing these advancements can lead to improved product quality and enhanced operational capabilities.

One of the primary advantages of using sheet metal CNC is its ability to produce intricate designs with high accuracy. Traditional machining methods often require extensive manual intervention and can lead to human error. In contrast, CNC technology minimizes variations in production, ensuring that each piece is consistent with the original design specifications. This level of precision is critical in industries where tolerances are tight and quality control is paramount.

The sheet metal CNC process typically involves several steps: design, programming, machining, and finishing. Initially, a detailed design is created using CAD (Computer-Aided Design) software, which outlines the specifications of the desired part. Once the design is finalized, it is transferred to CNC programming software that translates the design into machine-readable code. This code directs the CNC machine, guiding tools such as lasers, plasma cutters, or routers to execute the required operations on the sheet metal.

Another significant benefit of sheet metal CNC machining is its efficiency. The automation of the cutting and shaping processes greatly reduces production times compared to manual methods. This efficiency translates to lower labor costs and faster turnaround times for projects, making businesses more competitive in the market. Additionally, CNC machines can operate continuously, with minimal downtime, further enhancing productivity.

Moreover, the versatility of sheet metal CNC extends beyond simple cutting. It can handle various operations such as bending, punching, and forming, making it suitable for a wide range of applications across multiple industries. From automotive components to electronics housings, the ability to work with different materials like aluminum, stainless steel, and copper allows manufacturers to meet diverse customer demands.

In conclusion, sheet metal CNC machining is revolutionizing the manufacturing sector by offering unmatched precision, efficiency, and adaptability. As industries continue to evolve and demand more complex components, the role of CNC technology in sheet metal processing will undoubtedly grow, making it an essential tool for professionals in the mechanical processing field. Embracing these advancements can lead to improved product quality and enhanced operational capabilities.

Key words: