The Art and Science of Precision Metal Working: A Comprehensive Guide

Release time:

2025-06-14

Precision metal working is a vital process in the manufacturing sector, particularly in the realm of mechanical engineering and metal fabrication. It involves the use of advanced machinery and techniques to create metal components with exact specifications and tolerances. This specialized field is essential for producing parts that require high accuracy for the functionality and reliability of var

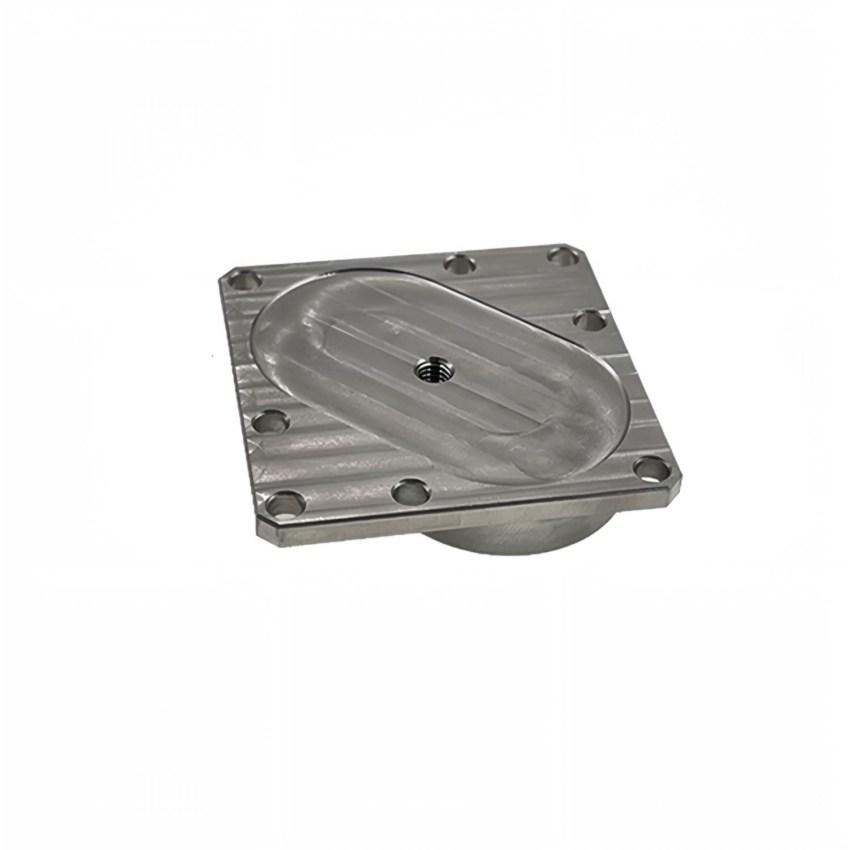

Precision metal working is a vital process in the manufacturing sector, particularly in the realm of mechanical engineering and metal fabrication. It involves the use of advanced machinery and techniques to create metal components with exact specifications and tolerances. This specialized field is essential for producing parts that require high accuracy for the functionality and reliability of various machines and devices.

One of the primary techniques used in precision metal working is CNC (Computer Numerical Control) machining. CNC machines are programmed to perform a wide range of tasks, including milling, turning, and drilling, with exceptional precision. The ability to automate these processes not only increases efficiency but also reduces the likelihood of human error, ensuring that the finished products meet the stringent quality standards required in many industries.

Another important aspect of precision metal working is the use of high-quality materials. The choice of metal can significantly impact the characteristics of the finished product, including strength, durability, and resistance to wear and corrosion. Common materials used in precision metal working include steel, aluminum, titanium, and various alloys, each selected based on the specific requirements of the application.

Precision metal working also encompasses various finishing processes, such as grinding, polishing, and coating. These finishing techniques are crucial for achieving the desired surface quality and enhancing the performance of the metal components. For example, a polished surface can improve the aesthetic appeal of a part while also reducing friction in mechanical applications.

In addition to traditional methods, the field of precision metal working is continually evolving with advancements in technology. Techniques such as additive manufacturing, or 3D printing, are being integrated into the metalworking process, allowing for the creation of complex geometries that were previously difficult or impossible to achieve. This innovation opens up new possibilities for design and production, making precision metal working even more versatile and efficient.

The applications of precision metal working are vast and varied, spanning industries such as aerospace, automotive, medical devices, and electronics. Each of these sectors relies on precision-engineered components to ensure safety, performance, and reliability. Whether it’s the intricate parts of an aircraft engine or the tiny components in a smartphone, precision metal working plays a crucial role in the success of modern technology.

In conclusion, precision metal working is a cornerstone of the manufacturing industry, combining artistry and engineering to produce high-quality metal components. By understanding the techniques, materials, and innovations associated with this field, manufacturers can enhance their production capabilities and deliver superior products that meet the demands of today’s market. Whether you are involved in manufacturing or simply interested in the field, a deeper insight into precision metal working can unveil the complexities and wonders of this essential process.

One of the primary techniques used in precision metal working is CNC (Computer Numerical Control) machining. CNC machines are programmed to perform a wide range of tasks, including milling, turning, and drilling, with exceptional precision. The ability to automate these processes not only increases efficiency but also reduces the likelihood of human error, ensuring that the finished products meet the stringent quality standards required in many industries.

Another important aspect of precision metal working is the use of high-quality materials. The choice of metal can significantly impact the characteristics of the finished product, including strength, durability, and resistance to wear and corrosion. Common materials used in precision metal working include steel, aluminum, titanium, and various alloys, each selected based on the specific requirements of the application.

Precision metal working also encompasses various finishing processes, such as grinding, polishing, and coating. These finishing techniques are crucial for achieving the desired surface quality and enhancing the performance of the metal components. For example, a polished surface can improve the aesthetic appeal of a part while also reducing friction in mechanical applications.

In addition to traditional methods, the field of precision metal working is continually evolving with advancements in technology. Techniques such as additive manufacturing, or 3D printing, are being integrated into the metalworking process, allowing for the creation of complex geometries that were previously difficult or impossible to achieve. This innovation opens up new possibilities for design and production, making precision metal working even more versatile and efficient.

The applications of precision metal working are vast and varied, spanning industries such as aerospace, automotive, medical devices, and electronics. Each of these sectors relies on precision-engineered components to ensure safety, performance, and reliability. Whether it’s the intricate parts of an aircraft engine or the tiny components in a smartphone, precision metal working plays a crucial role in the success of modern technology.

In conclusion, precision metal working is a cornerstone of the manufacturing industry, combining artistry and engineering to produce high-quality metal components. By understanding the techniques, materials, and innovations associated with this field, manufacturers can enhance their production capabilities and deliver superior products that meet the demands of today’s market. Whether you are involved in manufacturing or simply interested in the field, a deeper insight into precision metal working can unveil the complexities and wonders of this essential process.

Key words: