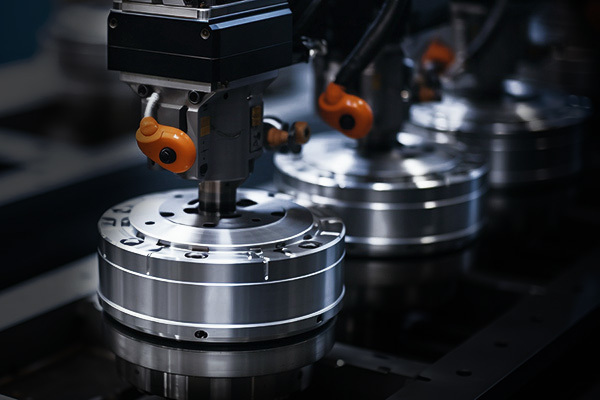

Aerospace CNC machining is a critical process for the production of highly precise and reliable components used in the aerospace industry. This advanced manufacturing technique ensures the creation of complex parts with tight tolerances, essential for the performance, safety, and durability of aircraft, spacecraft, and defense systems. CNC machining allows for the efficient production of parts such as turbine blades, structural components, engine parts, landing gear, and satellite components. These components must meet stringent quality standards due to the extreme conditions they face, such as high temperatures, pressure, and stress.

Using state-of-the-art CNC machines, manufacturers can work with a variety of high-performance materials, including titanium, aluminum alloys, and composite materials, which are commonly used in aerospace applications. These materials offer lightweight yet strong properties, which are essential for enhancing fuel efficiency, reducing weight, and improving overall performance.

CNC machining for aerospace also offers the advantage of consistency and repeatability. The automation provided by CNC machines ensures each part is produced with high precision, reducing human error and production time. With the aerospace industry's need for constant innovation and the design of more advanced systems, CNC machining provides manufacturers with the flexibility to create prototypes, low-volume production runs, or high-quantity production, all while maintaining tight tolerances.

Additionally, the ability to perform complex, multi-axis machining enables the production of intricate, detailed parts that meet the rigorous requirements of the aerospace industry. With aerospace CNC machining, manufacturers can achieve high-quality, cost-effective solutions that play a vital role in the development and enhancement of cutting-edge aerospace technology.

Keywords

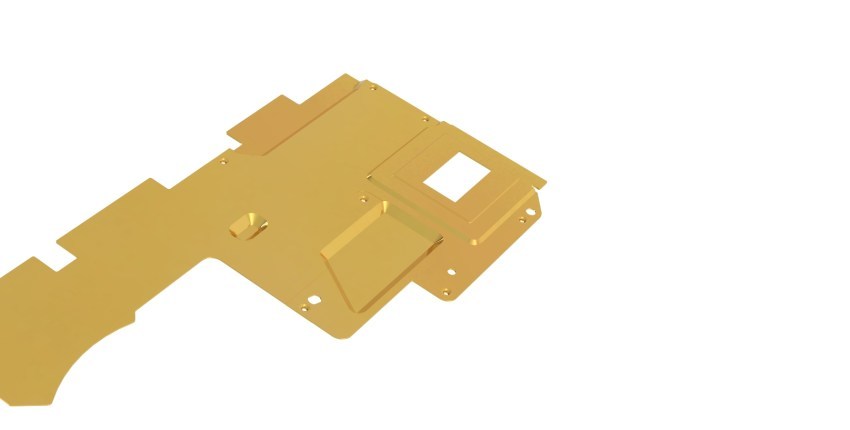

ISO certified bending die steel shim based on drawing With Good Product Quality

Contact Us

Classification

WHY CHOOSE US

QINGDAO HOLLAND PRECISION MACHINERY EQUIPMENT MANUFACTURING CO., LTD

Qingdao Holland Precision Machinery Equipment Manufacturing Co., Ltd. was established in 2015 and is located in Jihongtan Street Office, Chengyang District, Qingdao City, Shandong Province. The registered capital of the enterprise is 12 million RMB and the factory area is over 10000 square meters. We currently have over 100 employees and our products cover industries such as aerospace, semiconductors, mining equipment, new energy, agricultural machinery, military, medical equipment, automation equipment, drones, and home appliances. The company has passed ISO9001 quality system certification and ISO14001 environmental certification. We have a design and development team of 18 people, including 6 workshop technical engineers, who can design customized products according to customer requirements.

Industry Sector

Our products cover industries such as aerospace, semiconductors, mining equipment, new energy, agricultural machinery, military, medical equipment, automation equipment, drones, and home appliances.

new energy

Aerospace

agricultural machinery

Mining equipment

Major Customer

Our products cover industries such as aerospace, semiconductors, mining equipment, new energy, agricultural machinery, military, medical equipment, automation equipment, drones, and home appliances.

Related Products