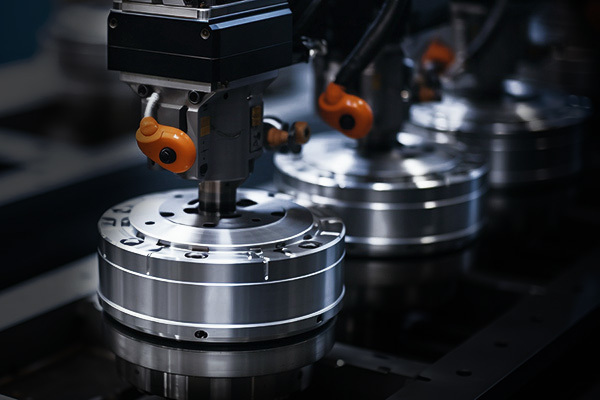

Precision machining sheet metal is a highly specialized manufacturing process that involves the use of advanced machinery to shape and modify sheet metal with extreme accuracy. This process includes various techniques such as CNC milling, turning, laser cutting, and stamping, ensuring the production of parts that meet the tightest tolerances. Precision machining is essential for creating complex and intricate components that require a high degree of detail, often used in industries like aerospace, automotive, electronics, and medical.

The process begins with raw sheet metal, typically made from materials such as aluminum, steel, stainless steel, or titanium, which is then carefully processed using cutting-edge machines. These machines are controlled by computer numerical control (CNC) systems, providing the highest level of accuracy and repeatability. CNC-controlled equipment ensures that parts are produced consistently, with minimal human error, while maximizing material utilization and minimizing waste.

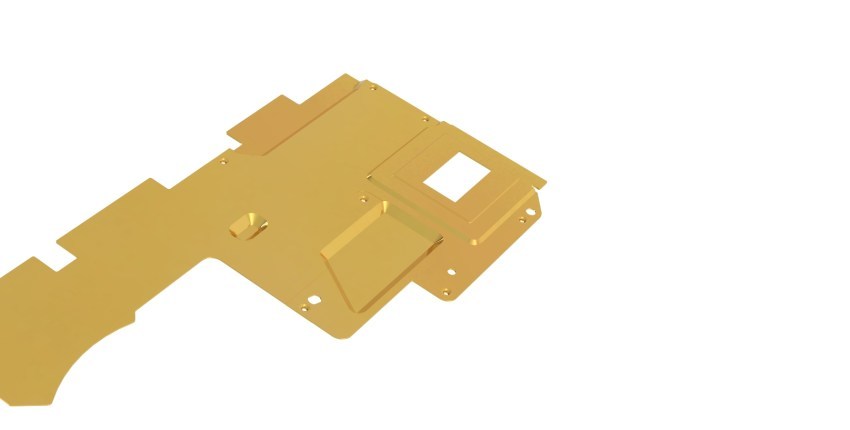

Precision machining of sheet metal allows manufacturers to create custom parts with complex geometries, precise hole placements, and smooth surface finishes. This capability is particularly useful for producing components such as enclosures, brackets, housings, and connectors, which require exact dimensions and surface quality.

One of the key advantages of precision machining sheet metal is its ability to deliver high-quality results in both prototype and production runs. Manufacturers can produce low-volume custom parts or large-scale orders with consistent quality and quick turnaround times. The process also supports flexibility in design, as modifications can be easily implemented without significant delays or retooling.

Moreover, precision machining ensures that parts are durable, functional, and meet strict industry standards. Whether for critical aerospace components, medical devices, or electronic housings, precision machining of sheet metal offers a reliable solution for producing high-performance, high-quality products. As industries continue to demand more complex designs and tighter tolerances, precision machining sheet metal remains an essential process in modern manufacturing.

Keywords

ISO certified sheet metal steel rail mining machinery With Quick response

Contact Us

Classification

WHY CHOOSE US

QINGDAO HOLLAND PRECISION MACHINERY EQUIPMENT MANUFACTURING CO., LTD

Qingdao Holland Precision Machinery Equipment Manufacturing Co., Ltd. was established in 2015 and is located in Jihongtan Street Office, Chengyang District, Qingdao City, Shandong Province. The registered capital of the enterprise is 12 million RMB and the factory area is over 10000 square meters. We currently have over 100 employees and our products cover industries such as aerospace, semiconductors, mining equipment, new energy, agricultural machinery, military, medical equipment, automation equipment, drones, and home appliances. The company has passed ISO9001 quality system certification and ISO14001 environmental certification. We have a design and development team of 18 people, including 6 workshop technical engineers, who can design customized products according to customer requirements.

Industry Sector

Our products cover industries such as aerospace, semiconductors, mining equipment, new energy, agricultural machinery, military, medical equipment, automation equipment, drones, and home appliances.

new energy

Aerospace

agricultural machinery

Mining equipment

Major Customer

Our products cover industries such as aerospace, semiconductors, mining equipment, new energy, agricultural machinery, military, medical equipment, automation equipment, drones, and home appliances.

Related Products