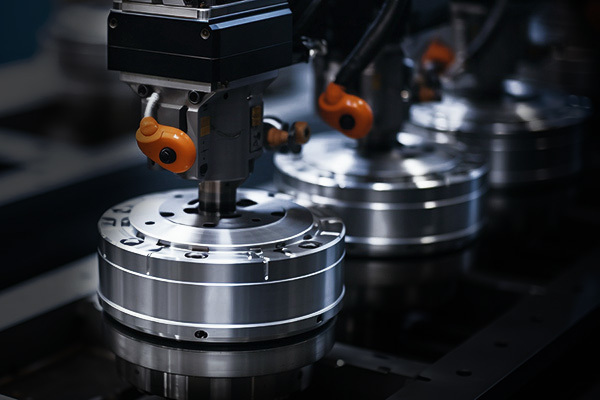

Alloy CNC machining is a highly precise and versatile manufacturing process used to shape and cut metal alloys into complex parts with tight tolerances. This technique is particularly effective for materials such as aluminum, titanium, stainless steel, and various other high-performance alloys. CNC (Computer Numerical Control) machines are employed to automate the machining process, ensuring consistent accuracy and high-quality results across large production runs or one-off custom components.

With alloy CNC machining, manufacturers can produce a wide range of parts, from intricate aerospace components to durable automotive parts and high-performance medical devices. The process allows for tight control over dimensional accuracy, surface finishes, and part geometry. CNC machines are capable of performing various tasks, including milling, turning, drilling, and grinding, all with precise control over the machining parameters.

One of the key advantages of alloy CNC machining is its ability to handle the specific requirements of high-strength alloys, which often have challenging material properties. These materials can be difficult to machine by conventional methods, but CNC machines can apply the correct speeds, feeds, and tooling to achieve the desired results efficiently. Furthermore, this process supports the production of parts with complex shapes, reduced material waste, and fast turnaround times.

Alloy CNC machining is essential for industries that demand high-performance, durable parts, such as aerospace, automotive, medical, and electronics. With the precision and flexibility it offers, this process remains one of the most reliable methods for producing high-quality alloy components.

Keywords

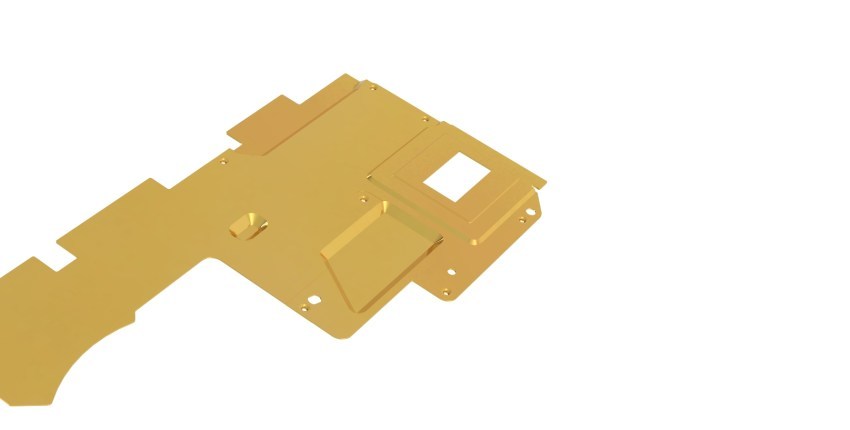

high quality bending alloy frame ODM With Low MOQ

Contact Us

Classification

WHY CHOOSE US

QINGDAO HOLLAND PRECISION MACHINERY EQUIPMENT MANUFACTURING CO., LTD

Qingdao Holland Precision Machinery Equipment Manufacturing Co., Ltd. was established in 2015 and is located in Jihongtan Street Office, Chengyang District, Qingdao City, Shandong Province. The registered capital of the enterprise is 12 million RMB and the factory area is over 10000 square meters. We currently have over 100 employees and our products cover industries such as aerospace, semiconductors, mining equipment, new energy, agricultural machinery, military, medical equipment, automation equipment, drones, and home appliances. The company has passed ISO9001 quality system certification and ISO14001 environmental certification. We have a design and development team of 18 people, including 6 workshop technical engineers, who can design customized products according to customer requirements.

Industry Sector

Our products cover industries such as aerospace, semiconductors, mining equipment, new energy, agricultural machinery, military, medical equipment, automation equipment, drones, and home appliances.

new energy

Aerospace

agricultural machinery

Mining equipment

Major Customer

Our products cover industries such as aerospace, semiconductors, mining equipment, new energy, agricultural machinery, military, medical equipment, automation equipment, drones, and home appliances.

Related Products